11 Years of Experience

Latest CAD/CAM Technology

Quick Quotation

About BakerBM Engineering

We have been established since 2007, providing an outstanding service to our current customer base.

We use the latest CAD/CAM technology to rapidly generate the most efficient machining cycles, ensuring run times are keep low and passing this saving onto our customers.

With our multi axis machines we regularly achieve “one hit machining” on our customers parts, reducing associated multiple set-up costs.

From a one-off prototype to a medium batch production run (10,000 parts), we are well equipped to meet your needs.

Contact us if you would like us to provide you with a quotation on your precision machined parts.

Why choose BakerBM Engineering?

As a producer of our own successful products, we have got vast experience in all areas of work.

Customer base

Compatibility

Punctuality

Design

Sectors

Diversity

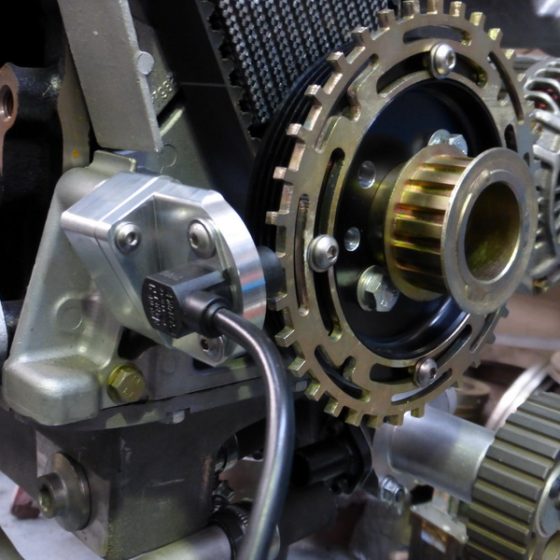

Our Machinery

Some of the machines we use.

TURNING

Hitachi Seiki Hi Cell-23 – CNC Lathe with Live Tooling, C- Axis + Y- Axis. 52mm Bar Capacity. Chuck work up to 220mm.

Mazak SQT10M – CNC Lathe with Live tooling C axis. 52mm Bar Capacity. Chuck work up to 160mm.

2x Emi Mec CNC 42 – CNC Lathe with 42mm Bar Capacity.

MILLING

Mikron VC500 – 3- Axis CNC Milling. 21 ATC 10,000RPM Spindle

Bridgecraft 412 – 3- Axis CNC Milling. 4th Axis capabilities. 12 ATC

CENTERLESS GRINDING

Cincinnati Centreless Grinding machine – Plunge and through grinding capabilities.

Years of Experience

Products Run Capacity

Completed Projects

Satistfied Clients

Location & Contact

We are based in the heart of the industrial West Midlands.

Our Address

BakerBM

Unit 5 Optical Park,

Middlemore Lane West

Redhouse Ind. Est.

Aldridge

WS9 8BG

Phone: 01922 276 606

Send us an email